Hot aisle containment is critical for maintaining cooling efficiency and preventing equipment overheating in a data center.

Also known as HAC, hot aisle containment allows data centers to make use of warm air, directing airflow to a return system. This increases the efficiency of cooling systems by at least a third – and sometimes more.

Technicians are vital to the management and upkeep of hot aisle containment, responsible for spotting inefficiencies and overlooked issues.

Read on for advice from our experts on how to walk the floor and identify opportunities to enhance hot aisle containment in your facility.

10 Ways to Identify and Improve Hot Aisle Containment

1. Inspect Rack Layout and Alignment

Begin by checking if racks are properly aligned back-to-back in the hot aisle and front-to-front in the cold aisle. As you do so, look for gaps between racks. These gaps can allow hot air to escape into the cold aisle.

Common oversights include inconsistent rack alignment across rows and racks that are out of position due to equipment changes or maintenance. If you see these, you’ll want to reposition misaligned racks and install blanking panels to fill empty rack spaces and prevent air leakage.

2. Check for Gaps and Leaks

Gaps around cable openings at the top or bottom of racks can leave room for leaks. Similarly, spaces under raised floors provide points at which air can easily escape or mix.

Look out for things like unsealed cable passthroughs or power conduits in the racks, along with open tiles or gaps under containment barriers.

Brush grommets and foam inserts can be used to seal cable openings. Unused floor tiles must always be closed, and it’s worth checking that containment barriers extend fully to the floor and ceiling.

3. Evaluate Roof Panels and Containment Barriers

Missing or damaged roof panels can drastically reduce efficiency in any hot aisle containment system, as can barriers that don’t fully enclose the hot aisle space.

We sometimes see issues like this occurring if panels are left off during equipment upgrades or repairs. Gaps between the top of the racks and the containment panels also allow for leakage and a subsequent reduction in efficiency.

Make sure any missing roof panels are replaced or reinstalled as soon as possible to avoid problems like this. Containment barriers should always extend to the ceiling, or modular barriers can be installed instead to close any gaps.

4. Monitor Temperature Variations

If you find temperature differences between racks in the same row, or uneven intake temperatures at the front of servers, you’ll need to make adjustments to improve the functioning of HAC.

Hot air often escapes around unsealed racks or through improperly closed cabinet doors. A lack of temperature sensors at different rack heights can also leave systems vulnerable to such discrepancies.

We always recommend adding temperature sensors at the top, middle, and bottom of racks to detect hotspots. Be ready to adjust airflow settings or reposition equipment to improve air distribution where necessary.

5. Assess Cable Management

If you have cables blocking airflow at the rear of racks in the hot aisle, or excess cable slack obstructing cooling pathways, a few simple adjustments will make all the difference to your hot air containment.

Overlooked cable bundles often cause airflow blockages. Unsecured cables hanging into the hot aisle containment area can also cause similar problems.

Organisation is key. Use cable trays and ties to organize and secure cables, and check to make sure that cables do not obstruct air vents or rear rack doors.

6. Examine Airflow Paths

Improper placement of perforated floor tiles (e.g., in hot aisles instead of cold aisles) and hot air recirculating into the cold aisle through gaps or open pathways nod to problems with your airflow paths.

If you’ve recently moved equipment or completed repairs, check that tiles haven’t been removed or misplaced. Look out for any recirculation hotspots near ends of rows or between racks as you do so.

Remember, perforated tiles should only be placed in cold aisles. If needed, you can block recirculation pathways using containment barriers or side panels.

7. Check Door Seals and Access Points

Keep an eye out for any gaps around hot aisle containment doors, or doors that have been left open or improperly closed.

Busy technicians can sometimes leave doors ajar during maintenance, leading to issues with hot air containment. Worn-out or missing door seals will also cause such problems over time.

To avoid these common problems, make sure your doors are self-closing, or ensure your staff are trained to double check they’re properly closed after use. Check seals regularly, replacing any damaged ones to maintain containment.

8. Look for “Hidden” Hotspots

If hot air is pooling in unused rack spaces or equipment bays, or you’ve identified air leaks around PDUs (Power Distribution Units) or at the rear of racks, the opportunity is there to improve hot air containment.

Hidden hotspots can occur when unused racks or spaces are left unsealed. Poorly ventilated PDUs will also contribute to the build up of heat.

It’s always worth using blanking panels to seal off unused rack spaces and reduce hotspots like these. You can also add exhaust fans or adjust airflow near PDUs to disperse heat efficiently.

9. Monitor Maintenance-Related Disruptions

Equipment that is moved without re-securing containment barriers can soon lead to HAC disruptions. It’s also possible that temporary openings have been left unaddressed following repairs, causing leaks.

All major maintenance should be followed up with thorough inspections to keep such disruption to a minimum. If maintenance has been undertaken in a hurry, it’s quite possible that barriers or seals haven’t been completed properly, so check these once maintenance is complete and staff aren’t under such time pressure.

Post-maintenance inspections are vital to the health of any good hot air containment system. Make checklists for maintenance teams to follow and you’ll soon prevent overlooked containment issues.

10. Evaluate Load Distribution

Load distribution is another key indicator of issues with HAC. Check for uneven equipment distribution across racks, and look out for any overloaded racks that could be generating excessive amounts of heat in localized areas.

When servers are clustered in specific racks, and others remain underutilized, there’s a clear opportunity to make efficiency improvements. Bear in mind manufacturers’ recommendations on load limits for racks and cooling systems as you check load distribution.

To prevent hotspots, you’ll want to balance equipment load across racks. Temperatures may well vary by a considerable amount in different areas; if this is the case you’ll need to redistribute equipment.

Additional Considerations for Hot Aisle Containment

The most important things to consider are proper rack alignment and airflow management. However, certain equipment and user behavior can create further HAC challenges. Bear in mind the thermal behavior of network switches and devices, as well as user actions that could compromise containment panels.

Network Devices and Airflow Direction

Network switches and other devices don’t always follow the same airflow patterns as servers. While most servers are designed to intake cool air from the front (cold aisle) and exhaust hot air from the rear (hot aisle), switches and other networking equipment will often blow air from side to side and exhaust air from the rear to the front, reversing the standard flow. The misalignment this causes can create hotspots and disrupt the containment strategy, trapping heat in the rack.

To avoid the problems this can cause, you’ll need to check each device’s airflow pattern before installation and use airflow guides or side airflow panels to direct air into the correct aisle. Place switches in racks where their airflow pattern won’t disrupt server cooling, or install them in separate network-specific racks. Fans can also be added for supplemental cooling, to assist airflow and prevent heat buildup.

User Actions that could Compromise Containment Panels

Containment panels are critical for maintaining the separation of hot and cold air. However, in shared data center environments or during maintenance, users will sometimes remove containment panels, such as roof panels and side barriers, to access equipment. This leaves facilities vulnerable if users forget to then reinstall them once completing tasks are complete.

The mixing of hot and cold air can lead to reduced cooling efficiency, higher energy costs and localized hotspots that can damage equipment.

Encourage staff to check panels as part of their routine inspections during walkthroughs. Staff members should also be fully trained to reinstall panels after removal. Emphasise the importance of maintaining containment during training programs.

Labels and signage can be used to remind users to replace panels. Sensors are also great at detecting airflow inconsistencies caused by missing panels.

Hot Air Containment at TRG

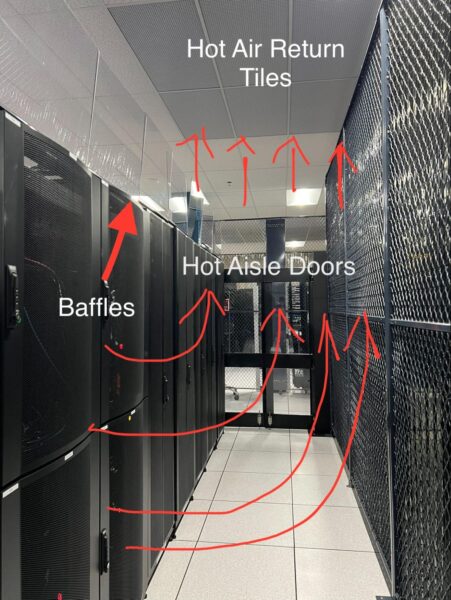

At TRG, we use methods such as baffles along the top of racks, hot aisle doors and blanking panels in racks to help with hot air containment. In doing so, we prevent hot air from mixing into the cold aisle, and instead channel it to the desired area.

Baffles on the top of racks and aisle doors help channel the hot air upwards into the ceiling (hot air plenum) through the hot air return tiles. From the ceiling, the hot air is then recycled back into the CRAC units in a different area. These containment methods enable us to keep equipment in the white space cool, and help the CRAC units to run efficiently. And that results in a huge saving on energy costs.

The below image shows how the hot exhaust air is blown out the back of the racks and flows upward to the hot air return tiles in the ceiling. Notice the baffles on the top left and hot aisle doors in the middle of the picture.

You’ll find two rooms of customer white space at TRG: DC1 and DC2. The spaces use a raised floor system, which is elevated multiple inches above the real floor. It consists of 2 ft x 2ft floor tiles, along a series of metal frames supported by pedestals.

All of the standard non-ported floor tiles are movable and adjustable with the use of a lifter tool. Each floor tile is composed of a metal shell filled with concrete, and every one has a laminate top surface panel.

This raised floor system gives us a 3ft tall void in between the floor tiles and the concrete slab, which is useful for running cables, and as a common plenum for the cold air coming from the CRAC units. Book a tour to see how it works in person.

Contact us to Find Out More

Our data centers are vital to the efficient running of hot air containment. Tasked with inspecting rack alignment, sealing gaps, monitoring temperatures, and managing cables, our team is always on hand to keep HAC working as effectively as possible.

If you’d like to learn more about HAC and how it works at TRG, don’t hesitate to contact us.

Looking for colocation?

For an unparalleled colocation experience, trust our expert team with three generations of experience